Dental 3D Printing.

SprintRay Ecosystem: The digital workflow that is designed for you.

At SprintRay, we build digital tools for dental professionals that foster opportunities for collaboration, innovation, and outstanding clinical results. Our workflow-driven portfolio of design solutions, materials, and printing ecosystems are designed to maximize the efficiency of your clinic.

Explore Applications

Order a Free Sample

3D Printing Materials

Clinically formulated, FDA clearedThe Biomaterial Innovation Lab is where 3D printing meets clinical dentistry. Our chemists and engineers bring you the best materials in the industry.

Explore Materials

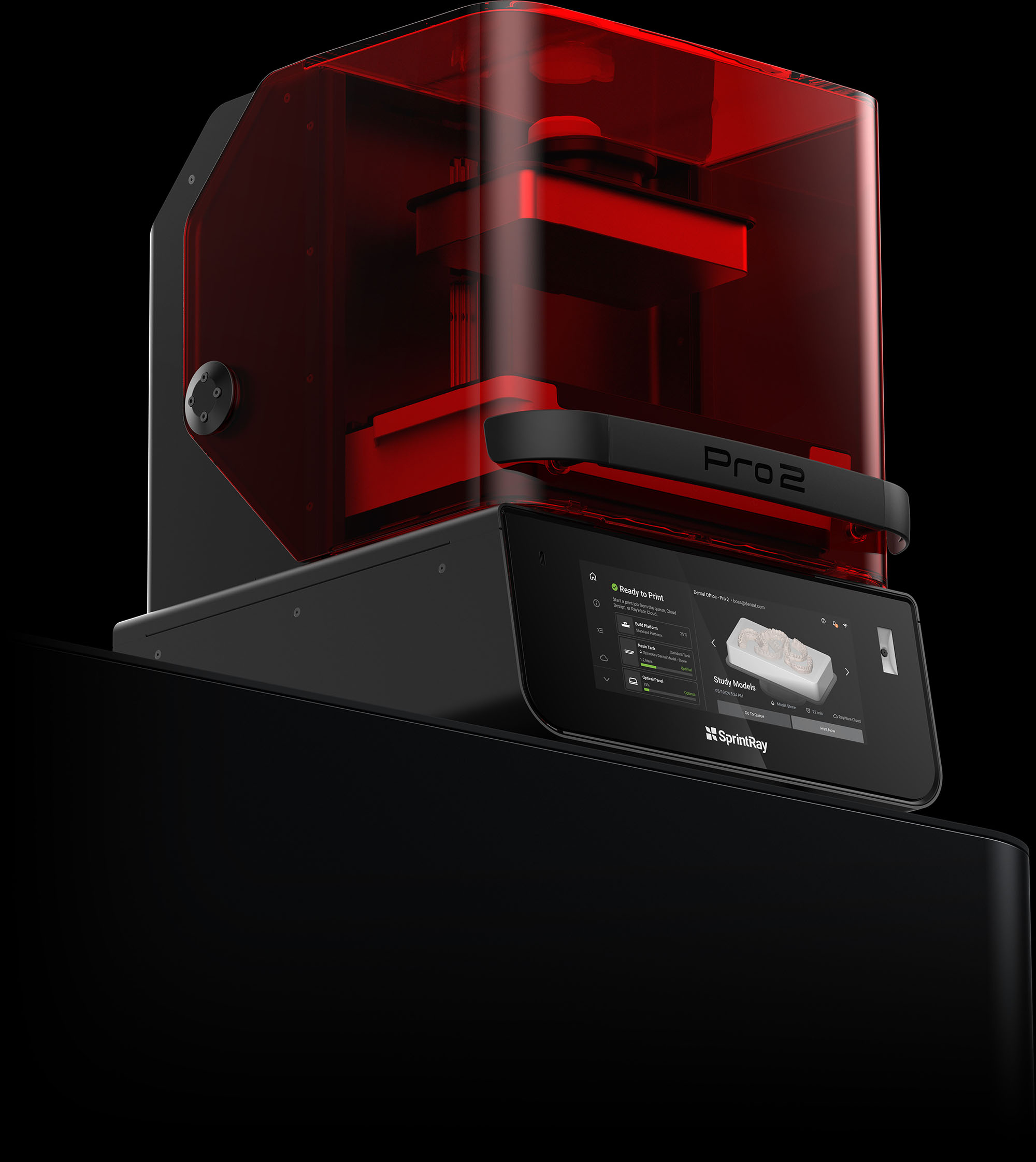

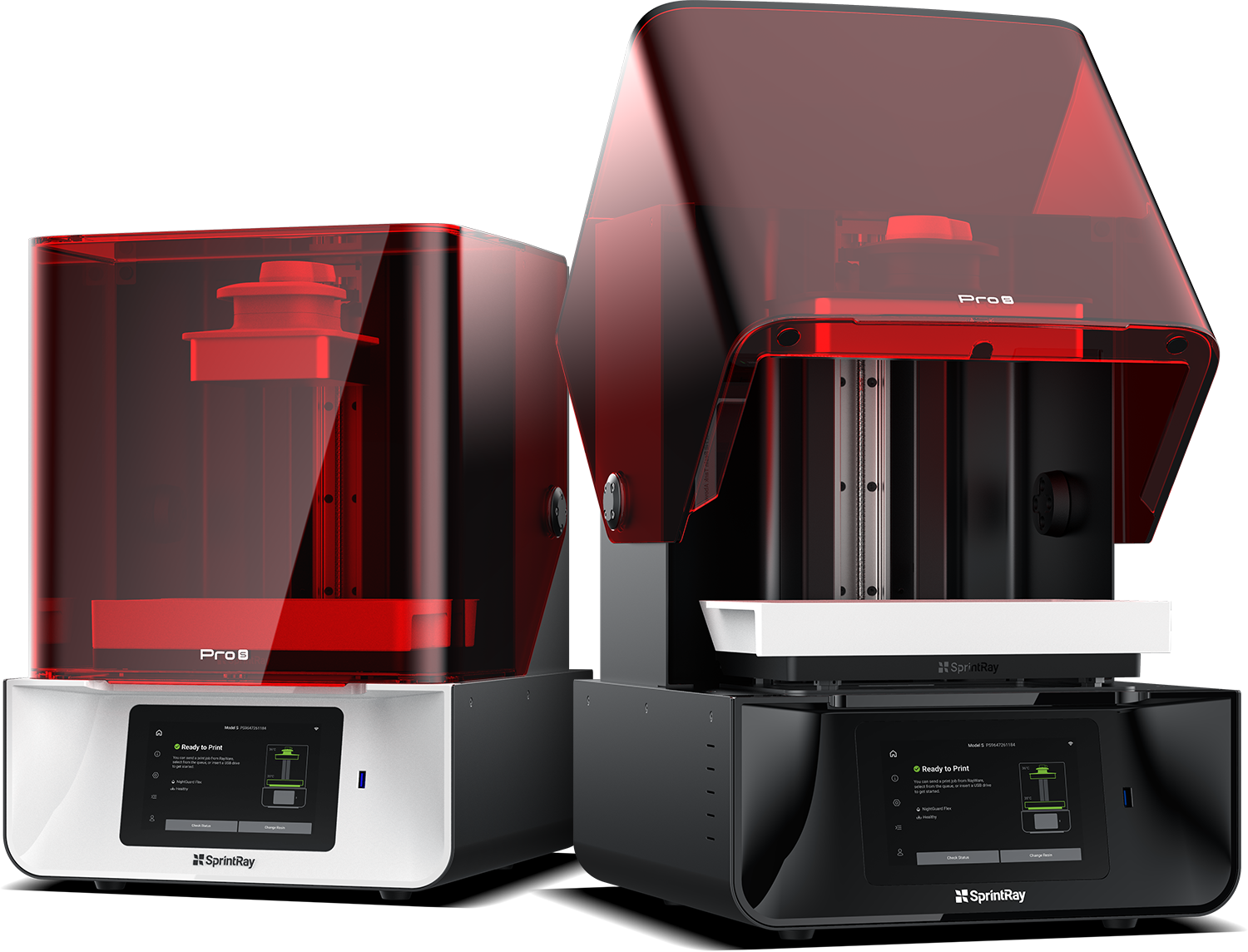

Pro S - The gold standard for dental 3D printing

The multitalented printer that can do it all. Optimize for batch printing or single restorations with incredible accuracy and ease of use with all-new printing kits.

See Pro S

Fast. Efficient. Enabled by kits

Apex Dentures - Crafted for strength, designed for beauty

The pinnacle of dental material science from the Biomaterial Innovation Lab, Apex sets the bar for a whole new class of 3D printed dentures.

Denture Workflow

NanoCure - Unlock next-gen printed appliances.

Elevate your prints to a new level of mechanical and aesthetic excellence with the world’s most advanced post curing system.

See NanoCure

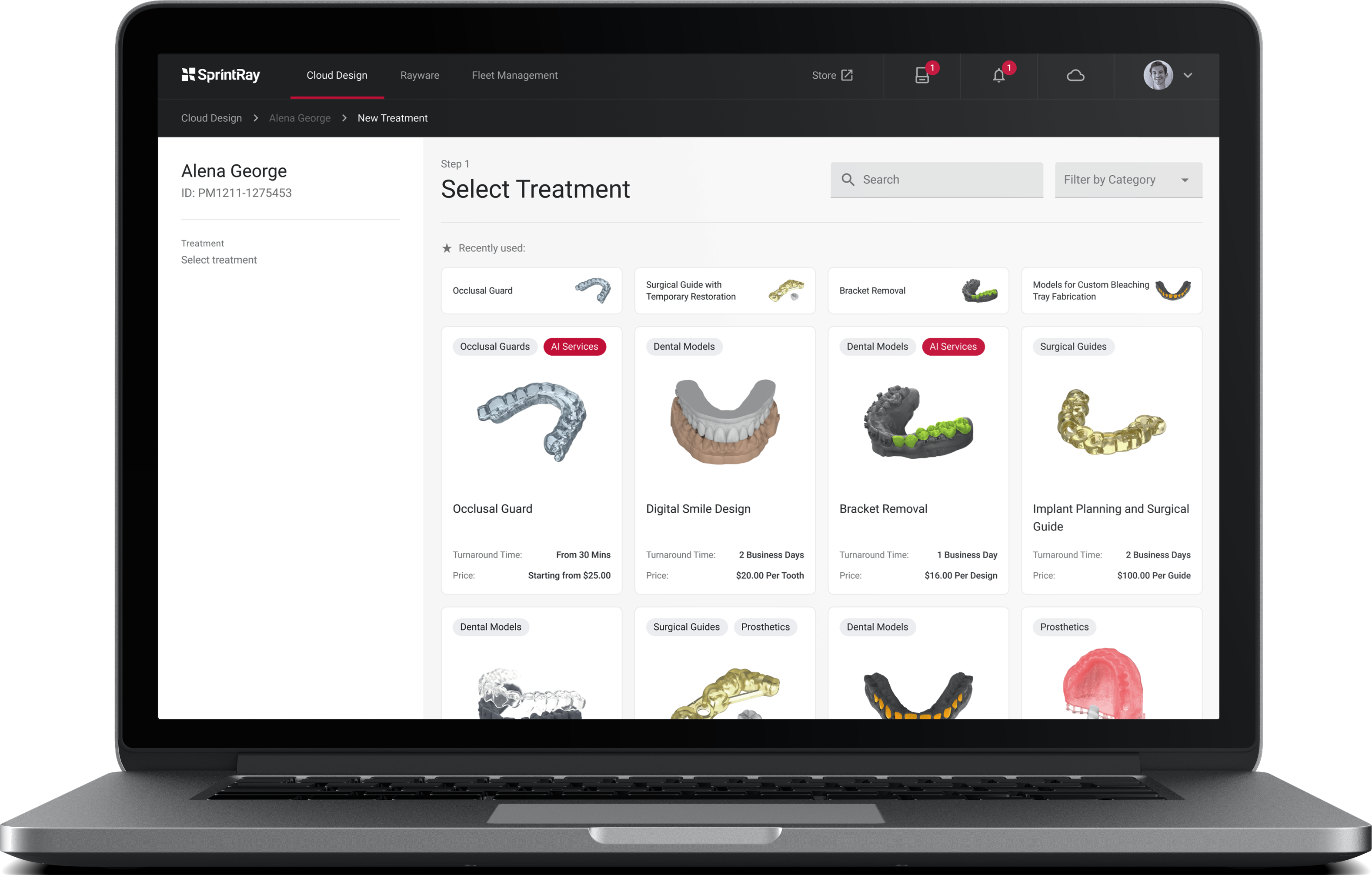

Cloud Design

Integrated appliance design in minutesSubmit your patient scans, then get a printable design. Leverage AI for a file in minutes or work with our expert design team for a full treatment plan.

NightGuard 2 - Next-generation strength and durability

NightGuard 2 materials offer second-gen strength, durability, and longevity while 5-minute AI design makes this the simplest workflow in dentistry.

Nightguard Workflow

ProWash S - More connected, more productive

Confidently wash and dry your 3D printed parts to prepare them for post curing. ProWash S automatically performs a two-cycle wash and then dries.

See ProWash S